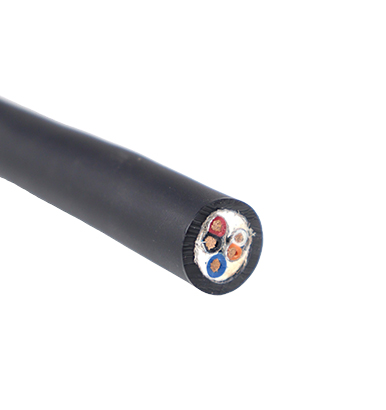

The Servo Motor drag chain cable is designed for precise power and signal transmission in dynamic industrial environments. Built for continuous-motion applications, this cable provides high flexibility, durability, and EMI resistance, ensuring reliable operation in robotic arms, CNC machinery, automated conveyor systems, and servo motor control networks.

Featuring multi-stranded copper conductors, oil- and abrasion-resistant insulation, and a durable outer jacket, the cable maintains signal integrity and power delivery under repetitive bending, twisting, and torsion. Its robust design minimizes electromagnetic interference and guarantees long-term reliability in demanding industrial settings.

High Flexibility: Withstands millions of bending cycles without conductor fatigue, ideal for drag chains.

Durable Construction: Resistant to oil, abrasion, chemicals, and mechanical stress.

Stable Power & Signal Transmission: Ensures precise servo motor control and communication.

EMI/RFI Shielding: Protects sensitive industrial electronics from interference.

Wide Temperature Range: Operates between -40°C and +80°C.

Certified Quality: CE, RoHS, UL, and ISO9001 compliant for global industrial applications.

Customizable Options: Available in multiple conductor counts, lengths, shielding types, and jacket materials.

| Parameter | Specification |

|---|---|

| Cable Type | servo motor drag chain cable |

| Conductor Material | Multi-Stranded Copper (OFC) |

| Conductor Size | 20–28 AWG |

| Number of Cores | 2–32 cores (customizable) |

| Insulation Material | PE / XLPE / TPE |

| Shielding | Foil + Braided Copper (optional) |

| Outer Jacket Material | PVC / PUR / LSZH (oil- and abrasion-resistant) |

| Voltage Rating | 300V – 600V |

| Temperature Range | -40°C to +80°C |

| Minimum Bending Radius | 7.5 × Cable Diameter |

| Flame Resistance | UL VW-1 / IEC 60332-1 |

| Applications | Robotics, CNC Machines, Servo Drives, Automated Conveyor Systems |

| Certifications | CE / RoHS / UL / ISO9001 |

Supports servo motor communication and control signals, ensuring precise movement and operation of robotic arms and automated gantry systems.

Provides stable and reliable data and power transmission for motion controllers and servo drives in CNC machines.

Delivers continuous-motion power and signals for conveyors, reducing downtime and enhancing operational efficiency.

Integrates with PLC systems, sensors, and actuators, enabling real-time control and monitoring in automated production lines.

Ensure the system is powered off before installation.

Verify cable specifications meet your servo motor and controller requirements.

Inspect the cable for mechanical damage or insulation defects.

Route the cable through the drag chain, maintaining the minimum bending radius.

Secure the cable with clamps or supports to prevent excessive movement.

Connect the cable to servo drives, controllers, or actuators, ensuring correct polarity and shielding connection.

Avoid twisting, knotting, or sharp bends in the cable.

Separate the cable from high-voltage lines to prevent interference.

Regularly inspect the cable for wear and tear, particularly in high-motion areas.

Document installation and maintenance for future reference.

Proper maintenance is essential to ensure long-term performance and safety.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Visual Inspection | Every 3 months | Check for cuts, abrasions, or jacket damage. |

| Connector Check | Every 6 months | Ensure connectors are secure and corrosion-free. |

| Flexibility Test | Annually | Verify bending performance and conductor integrity. |

| Electrical Testing | Annually | Measure continuity, insulation resistance, and signal quality. |

| Replacement | Every 3–5 years | Replace if insulation is damaged or signals degrade. |

Even high-quality servo motor drag chain cables can experience operational issues. Below are common faults and troubleshooting methods:

| Issue | Possible Cause | Solution |

|---|---|---|

| Signal Loss | Damaged conductors or shielding | Inspect cable for cuts or breaks; replace if necessary. |

| Interference / EMI | Insufficient shielding or proximity to power lines | Ensure proper shielding; separate from high-voltage lines. |

| Connector Fault | Loose or corroded connectors | Tighten or replace connectors; clean terminals. |

| Reduced Flexibility | Conductor fatigue or jacket wear | Replace cable if bending performance deteriorates. |

| Overheating | Excessive current load | Verify cable rating matches system requirements; reduce load. |

Always power off equipment before installation or maintenance.

Use personal protective equipment (PPE) when handling cables in industrial settings.

Avoid exposure to heat sources, chemicals, or sharp objects.

Adhere to minimum bending radius to prevent conductor fatigue.

Maintain clear routing to prevent cable entanglement or mechanical stress.

The Servo Motor Drag Chain Cable undergoes extensive testing to ensure mechanical durability, signal integrity, and safety compliance.

| Test Type | Standard / Method | Purpose |

|---|---|---|

| Flex Test | ISO 6722-1 | Verify cable can withstand millions of bending cycles. |

| Electrical Continuity | IEC 60228 | Ensure consistent conductor performance and minimal signal loss. |

| Insulation & Voltage Withstand | IEC 60502 | Test insulation integrity under rated voltage. |

| Flame Resistance | UL 1581 / IEC 60332-1 | Confirm fire safety compliance. |

| EMI/RFI Shielding | EN 50288-3 | Ensure reduction of electromagnetic interference. |

| Temperature Cycling | IEC 60811 | Test performance under extreme temperatures. |

| Mechanical Abrasion | IEC 60811 | Verify jacket resistance to wear and tear. |

Pre-Check: Inspect the cable, connectors, and drag chain before powering up the system.

Power-On: Slowly energize the servo motor system and monitor initial signal transmission.

System Test: Run initial movement tests to ensure smooth motion and accurate control.

Monitoring: Continuously monitor signal quality and servo response during operation.

Routine Maintenance: Follow scheduled inspections and testing to maintain cable performance.

Warranty: 24 months for manufacturing defects.

Replacement Policy: Free replacement for verified quality issues during the warranty period.

Technical Assistance: 24/7 support for troubleshooting, installation guidance, and system integration.

Available for large-scale automation projects, including installation assistance, cable routing optimization, and preventive maintenance guidance.

| Packaging Type | Details |

|---|---|

| Reels / Drums | Prevent twisting and tangling; ideal for long-length cables. |

| Cut-to-Length Coils | Custom lengths available for specific installations. |

| Labeled Packaging | Includes part number, batch number, and inspection certificate. |

| Export Packaging | Moisture-proof wrapping and sturdy crates for safe shipment. |

Lead Time: 2–4 weeks depending on order quantity and customization.

Delivery Terms: EXW / FOB / CIF / DDP available for international customers.

The Servo Motor Drag Chain Cable delivers high-flexibility, durability, and reliable signal transmission for industrial automation and servo control systems. Ideal for robotics, CNC machinery, automated conveyor systems, and factory automation, it ensures precise motor control, EMI resistance, and long-term operational reliability.

With CE, RoHS, UL, and ISO certifications, supported by comprehensive technical guidance, maintenance schedules, and after-sales service, this cable is the preferred solution for engineers, system integrators, and automation professionals seeking reliable, high-performance servo motor cabling.

Choosing the right Servo Motor Drag Chain Cable is critical for stable, high-speed, and interference-free servo motor operation in industrial automation. Combining mechanical flexibility, EMI shielding, and robust insulation, this cable ensures efficient, safe, and long-lasting operation in modern factories, CNC systems, and robotic automation setups.

For technical consultation, custom cable orders, or installation guidance, our engineering team provides expert support, ensuring optimal performance and reliability of your servo motor systems.

אתר זה משתמש בקובצי Cookie כדי להבטיח שתקבל את החוויה הטובה ביותר באתר שלנו.