In today’s industrial world, Flexible Power Control Cables play a critical role in ensuring efficient power transmission and control across machinery, automation systems, and electrical networks. Designed to deliver stable performance under dynamic conditions, these cables combine flexibility, durability, and excellent electrical conductivity.

Whether used in factory automation, power distribution, construction equipment, or marine applications, flexible control cables provide a dependable link between power sources and operating equipment — ensuring safety, performance, and productivity.

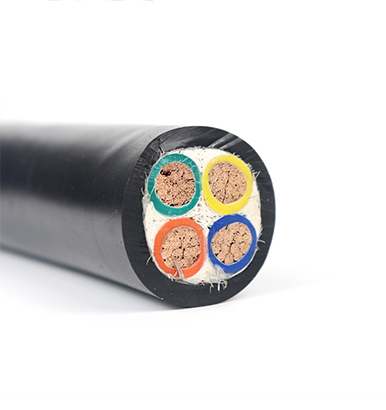

A Flexible Power Control Cable is a multi-core electrical cable engineered to carry power and control signals while allowing frequent bending and movement without mechanical fatigue. It typically features:

Flexible copper conductors (Class 5 or 6)

PVC, XLPE, or rubber insulation

Oil-, heat-, and abrasion-resistant sheathing

Shielding options for electromagnetic protection

These cables are used in industrial automation, machine tools, assembly lines, robotics, and building control systems, where flexibility and reliability are essential.

| Feature | Description | Benefit |

|---|---|---|

| High Flexibility | Fine-stranded copper conductors and flexible insulation materials | Easy installation and bending without damage |

| Durability | Resistance to oil, UV, flame, and mechanical stress | Long service life in harsh environments |

| Electrical Stability | Consistent voltage and signal transmission | Reliable performance for control and power circuits |

| Safety Compliance | Meets IEC, UL, and RoHS standards | Safe and eco-friendly use |

| Temperature Range | -40°C to +90°C (depending on material) | Suitable for various industrial environments |

| Customization | Available in multiple cores, sizes, and jackets | Fits diverse customer applications |

Flexible Power Control Cables are widely used in factory automation systems, connecting sensors, controllers, and actuators. Their flexibility supports repetitive machine movement, reducing the risk of cable fatigue and downtime.

In CNC machines, conveyors, and robotic arms, these cables provide reliable power delivery and control signal transmission even in continuous flexing conditions.

Used in switchboards, control panels, and power supply units, flexible cables help distribute power safely within buildings and industrial plants.

In solar and wind power installations, cables with high UV and weather resistance are used for long-term outdoor operation.

Marine-grade flexible power cables resist saltwater, oil, and vibration, ensuring performance in shipbuilding and offshore applications.

| Parameter | Specification |

|---|---|

| Conductor Material | Tinned or bare copper (Class 5) |

| Insulation Material | PVC / XLPE / EPR |

| Rated Voltage | 300/500V, 450/750V, or 0.6/1kV |

| Test Voltage | 2000V / 5 min |

| Operating Temperature | -40°C to +90°C |

| Minimum Bending Radius | 7.5 × cable diameter |

| Flame Retardancy | IEC 60332-1 compliant |

| Certification | CE / RoHS / ISO / UL (optional) |

At every stage of production, strict quality control ensures that each cable meets international standards. Our company follows a multi-step inspection process covering raw materials, electrical performance, and mechanical reliability.

Raw Material Testing – Copper purity, insulation resistance, and tensile strength verified.

In-Process Monitoring – Continuous extrusion and stranding inspection.

Electrical Testing – Voltage withstand, conductor resistance, and insulation performance.

Environmental Testing – Heat aging, oil immersion, and cold flexibility tests.

Final Inspection – Dimensional accuracy, marking verification, and packing control.

Our cables meet or exceed the following international standards:

IEC 60227 / IEC 60245

EN 50525

UL & CSA approvals (for North America)

RoHS and REACH environmental compliance

ISO 9001:2015 Quality Management System

These certifications demonstrate our commitment to safety, performance, and environmental responsibility.

We provide OEM & ODM solutions to meet the unique needs of our clients. Whether you need specific conductor sizes, insulation colors, or marking requirements, our engineering team delivers tailor-made cable solutions.

Customizable options include:

Conductor cross-sections and materials

Jacket materials (PVC, PUR, TPE, rubber)

Color coding and numbering

Shielded or unshielded designs

Packaging and labeling for export markets

Customer satisfaction is our top priority. We offer comprehensive after-sales support to ensure the long-term reliability and performance of every product.

All Flexible Power Control Cables come with a minimum 12-month warranty against manufacturing defects. Extended warranty terms are available for bulk orders or special applications.

Our engineering team provides:

Installation and wiring guidance

Troubleshooting and diagnostics

Compatibility assessments for equipment and systems

We maintain partnerships with international freight forwarders to ensure safe and timely delivery to all major global markets.

To maximize the service life and performance of your Flexible Power Control Cables, follow these professional maintenance guidelines:

Avoid exceeding the recommended bending radius during installation.

Use proper strain reliefs at both ends to prevent tension on connectors.

Ensure cables are not twisted or compressed during movement.

Perform visual inspections for abrasion, cracking, or discoloration.

Test insulation resistance periodically to ensure electrical integrity.

Check connectors for tightness and corrosion.

Wipe with a dry or slightly damp cloth; avoid chemical solvents.

Store in a cool, dry, and ventilated area, away from direct sunlight.

Keep cables coiled properly to prevent internal stress.

If any damage or degradation is observed, replace the cable immediately to prevent electrical failure or safety risks.

20+ years of manufacturing experience

Strict quality management and testing

Competitive factory pricing

Fast delivery and strong OEM capability

Professional global technical support

Our Flexible Power Control Cable is not only a product but a complete solution designed to meet your operational and safety requirements — from design and production to delivery and after-sales service.

The Flexible Power Control Cable is an indispensable component in modern industrial and electrical systems, offering reliable power transmission, superior flexibility, and long-term durability. Backed by certified quality assurance, responsive service, and expert engineering support, our cables ensure consistent performance across the most demanding applications.

Partner with us to experience dependable energy and control connectivity that powers your business success.

אתר זה משתמש בקובצי Cookie כדי להבטיח שתקבל את החוויה הטובה ביותר באתר שלנו.