Flexible drag chain cables are specially engineered for dynamic applications where continuous bending, flexing, and movement are required. Unlike standard cables, they are built to perform reliably inside cable carriers or drag chains, preventing tangling, wear, and electrical failures.

This guide covers technical services, operational tips, installation steps, and user feedback, providing a professional knowledge base for engineers, buyers, and industrial operators.

A flexible drag chain cable (also called cable carrier cable or energy chain cable) is designed to move with machinery components while maintaining stable power and signal transmission.

High bending resistance for millions of cycles

Jackets resistant to oil, chemicals, and abrasion

Stable data and power transmission

Long service life in automation and robotics

Flexible drag chain cables are essential in industries such as:

CNC machines – precision tools requiring high motion stability

Robotics – articulated robotic arms and conveyors

Automated production lines – continuous operation under high cycle rates

Material handling systems – cranes, gantries, and warehouse automation

Packaging equipment – fast-moving machinery with repetitive cycles

Professional suppliers should provide not just products, but also technical expertise and service.

| Service Type | Description |

|---|---|

| Pre-sales consultation | Selection of correct cable type, conductor size, and jacket material for application. |

| Customization | Tailored solutions for extreme conditions (high-speed, cleanroom, outdoor use). |

| Testing & Certification | Compliance with UL, CE, RoHS, and specific industrial standards. |

| After-sales technical support | Installation guidance, troubleshooting, and maintenance advice. |

| Training & Documentation | Manuals, installation guides, and staff training programs. |

✅ A strong technical service package reduces downtime, improves cable lifespan, and ensures customer satisfaction.

To achieve maximum efficiency and reliability, operators should follow these best practices:

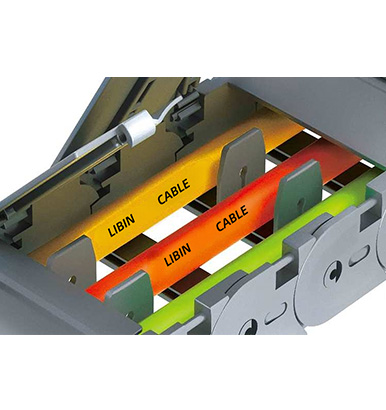

Do not overload the drag chain with too many cables. Use separators to prevent tangling.

Follow manufacturer specifications for bending radius to avoid stress fractures.

Fasten cable ends with strain relief devices, but avoid over-tightening, which can damage the jacket.

Check for jacket wear, cracks, and abnormal bends during routine maintenance.

For dusty environments → use abrasion-resistant jackets.

For oily environments → choose oil-resistant materials.

For outdoor use → select UV and weather-resistant designs.

Correct installation is essential for safety and long service life.

Select cables according to voltage, current, and signal requirements.

Check drag chain dimensions and bending radius.

Prepare separators if multiple cables are used.

Lay cables loosely inside the drag chain without twisting.

Ensure cables can move freely within the carrier.

Maintain equal spacing to prevent contact abrasion.

Fix cable ends with strain relief at both moving and stationary points.

Avoid sharp clamps that can cut the outer jacket.

Run the drag chain slowly to check for smooth motion.

Inspect for snags, twisting, or tension points.

Confirm that cables follow the designed path without interference.

Record installation details for maintenance logs.

Customer feedback is crucial for continuous product improvement. Below are typical comments from industrial users:

| Industry | User Feedback |

|---|---|

| CNC machining | “After switching to flexible drag chain cables, we reduced downtime by 30%.” |

| Robotics | “The cables run smoothly inside robotic arms with no signal loss.” |

| Packaging industry | “High-speed operations are more stable and maintenance intervals are longer.” |

| Material handling | “Durable even under heavy loads and continuous operation in harsh environments.” |

| Automation integrator | “Easy installation with excellent technical support from the supplier.” |

אתר זה משתמש בקובצי Cookie כדי להבטיח שתקבל את החוויה הטובה ביותר באתר שלנו.